Materials Science for Hydrogen Energy

Staff:

ABE Takayuki AKAMARU Satoshi HAGIWARA Hidehisa

1. Preparation of high-performance functional particles

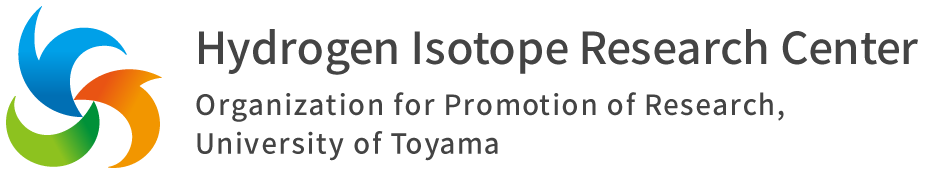

Functional particles, which are widely used in industrial products, commodities, and others, are recently expected to have further high performances, because of their expanded applications. The functions of the particles are well-known to be mainly determined by the nature of the surfaces. Therefore, the “design of the particle surfaces” is important to improve the performances of the functional particles. Thus, we developed new plasma-based surface modification systems for particles (polygonal barrel-sputtering method, polygonal barrel-plasma chemical vapor deposition method, polygonal barrel-plasma treatment method). Unlikely to the conventional methods such as wet processes, these systems are categorized as dry processes and can control the particle surface modification at nano-level. By these features, our methods are the one and only technique in the world that allow the design of the particle surfaces.

Some experimental results are shown below. For our methods, the particle surfaces can be uniformly modified with thin films composed of metals, carbon materials, metal oxides, etc. The particle surface modification with nanoparticles makes it possible to prepare various catalysts with high activities, e.g. Ru/TiO2 catalysts prepared by the polygonal barrel-sputtering method decrease the reaction temperature of CO2 methanation (CO2 + 4H2 → CH4 + 2H2O) by ca. 200ºC, as compared to those prepared by a conventional impregnation method. Furthermore, we have succeeded in the addition of ultra-hydrophobicity (contact angle of water drop on a sample: over 150℃) to common polymer particles by the surface fluorination using the polygonal barrel-plasma treatment method. Thus, our plasma-based particle surface modification systems are useful for improving the performances of functional particles including catalysts, electrocatalysts, cosmetics, and so on.

2. Photocatalytic water splitting for solar energy conversion

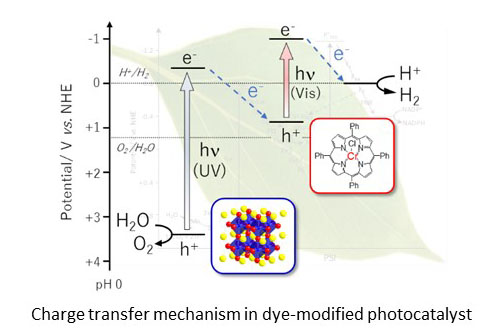

Sunlight is the continuous light including ultraviolet, visible, and infrared light, and it is a key factor for improving energy conversion efficiency of photocatalysts to use wide wavelength region of sunlight. In this study, we use metal complexes (e.g. porphyrins or phthalocyanines) or organic dyes as a visible light absorber for the inorganic semiconductor photocatalysts to improve the photocatalytic activity by increasing light absorption amounts. It is important to suppress the recombination of photo-generated electrons and holes for the improvement of the photocatalytic activity. In this dye-modified photocatalyst system, long-time charge separation is achieved by a similar charge transfer mechanism with photosynthesis. We study the modification effects of loading novel metal or metal oxide particles for improving surface reactivity and selectivity, to develop highly active photocatalysts for solar energy conversion.

3.Development of photo-thermochemical hybrid water-splitting process

The thermochemical water decomposition with iodine and sulfur (IS process) which consists of three chemical reactions, hydrogen iodide decomposition, sulfuric acid decomposition, and Bunsen reaction, is expected as a promising hydrogen production process for practical use. Recently, solar thermal IS process has been actively studied from a viewpoint of the renewable energy conversion. We have developed “photo-thermochemical hybrid water-splitting process” which combined the photocatalytic hydrogen iodide decomposition with the catalytic sulfuric acid decomposition and Bunzen reaction for utilizing whole sunlight energy, and studied highly active and durable catalyst materials for this process.